In the fast-paced world of semiconductor manufacturing, precision and reliability are paramount. The intricate processes involved in creating these tiny yet powerful components require advanced techniques and technologies to ensure optimal performance.

One such technology that plays a crucial role in semiconductor manufacturing is vacuum technology. In this article, we delve into the realm of vacuum technology in semiconductor manufacturing, exploring its significance, techniques, principles, deposition processes, and the contributions of industry leaders like Pfeiffer Vacuum.

Understanding Vacuum Semiconductors

At its core, a vacuum semiconductor refers to a semiconductor device or component manufactured under vacuum conditions. Vacuum environments are devoid of air and other contaminants, providing a pristine setting for semiconductor fabrication.

By eliminating air molecules and impurities, vacuum environments minimize contamination, enhance process control, and optimize the performance and reliability of semiconductor devices.

Exploring Vacuum Techniques

Vacuum techniques encompass a wide range of methodologies used to create and maintain vacuum environments in semiconductor manufacturing. These techniques include physical vapor deposition, chemical vapor deposition, molecular beam epitaxy, and ion implantation, among others.

Each technique has its unique advantages and applications, catering to diverse semiconductor manufacturing requirements.

The Principle of Vacuum Systems

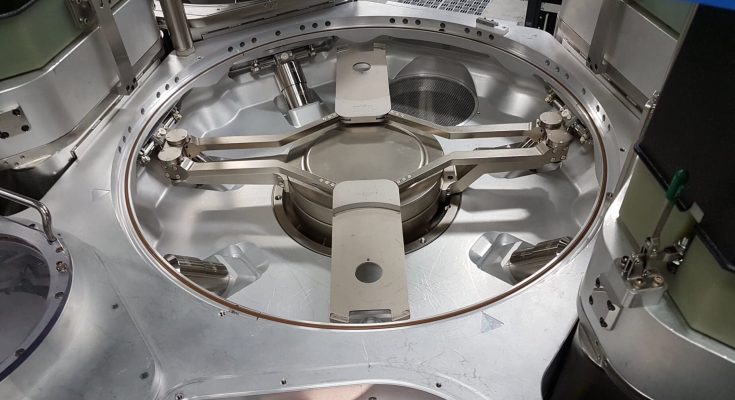

The principle of a vacuum system revolves around creating and sustaining a low-pressure environment by removing air and other gases from a sealed chamber. This is typically achieved using vacuum pumps, which draw air molecules out of the chamber, creating a vacuum.

The efficiency and effectiveness of vacuum systems depend on factors such as pump type, vacuum level, and chamber design.

Vacuum Deposition Processes

Vacuum deposition processes play a pivotal role in semicondutor manufacturing, enabling the precise deposition of thin films and coatings onto semiconductor substrates. These processes include physical vapor deposition,

Where materials are evaporated or sputtered onto a substrate, and chemical vapor deposition, where chemical reactions deposit thin films onto substrates. Vacuum deposition processes ensure uniform film thickness, high purity, and excellent adhesion, critical for semiconductor performance.

Pfeiffer Vacuum: Leading the Way in Vacuum Technology for Semiconductors

Pfeiffer Vacuum is a renowned name in the field of vacuum technology, offering a comprehensive range of vacuum solutions tailored to the semiconductor industry. With a rich history of innovation and expertise, Pfeiffer Vacuum provides cutting-edge vacuum pumps, valves, and systems designed to meet the demanding requirements of semiconductor manufacturing.

Pfeiffer Vacuum’s commitment to quality, reliability, and performance makes it a trusted partner for semiconductor manufacturers worldwide.

Conclusion

Vacuum technology plays a vital role in semiconductor manufacturing, offering precise control, contamination-free environments, and enhanced process efficiency. By leveraging vacuum techniques and principles, semiconductor manufacturers can achieve superior device performance, reliability, and yield.

As industry leaders like Pfeiffer Vacuum continue to innovate and advance vacuum technology, the future of semiconductor manufacturing looks brighter than ever before. Embracing vacuum technology is not just a choice but a necessity for semiconductor manufacturers striving for excellence in today’s competitive landscape.